Flat Orthogonal XY Scanning without Scanner Bow

Park's Crosstalk Elimination scanner structure removes scanner bow, allowing flat orthogonal XY scanning regardless of scan location, scan rate, and scan size. It shows no background curvature even on flattest samples, such as an optical flat, and with various scan offsets. This provides you with a very accurate height measurement and precision nanometrology for the most challenging problems in research and engineering.

Decoupled XY and Z Scanners

The fundamental difference between Park and its closest competitor is in the scanner architecture. Park’s unique flexure based independent XY scanner and Z scanner design allows unmatched data accuracy in nano resolution further improved with NX AFM Head (Z scanner) powered by NX AFM electronic controller.

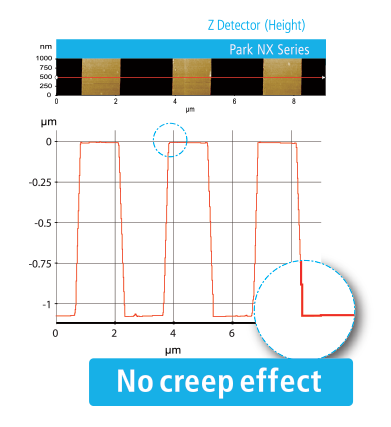

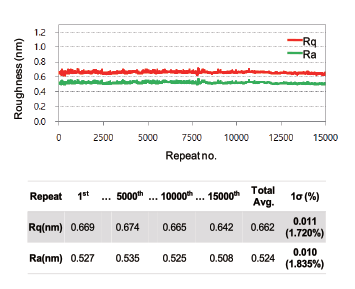

Industry Leading Low Noise Z Detector

Park AFMs are equipped with the most effective low noise Z detectors in the field, with a noise of 0.02 nm over large bandwidth. This produces highly accurate sample topography and no edge overshoot. Just one of the many ways Park NX series saves you time and gives you better data.

Accurate Sample Topography Measured by Low Noise Z Detector

- Uses low noise Z detector signal for topography

- NX electronic controller provides low Z detector noise of 0.02 nm over large bandwidth

- Has no edge overshoot at the leading and trailing edges

- Needs calibration done only once at the factory

Sample: 1.2 μm Nominal Step Height

(9 μm x 1 μm, 2048 pixels x 128 lines)

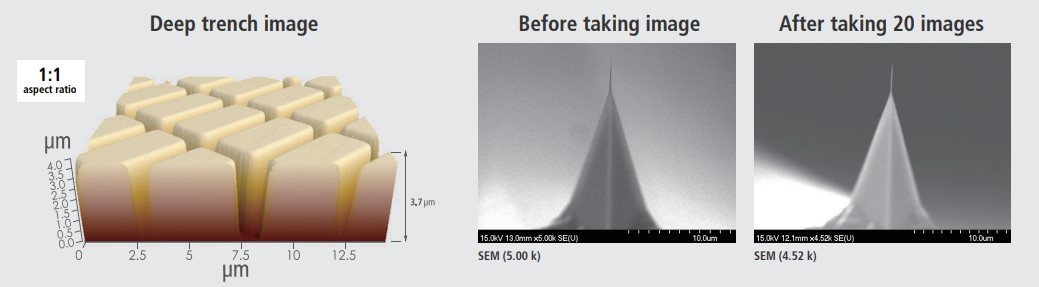

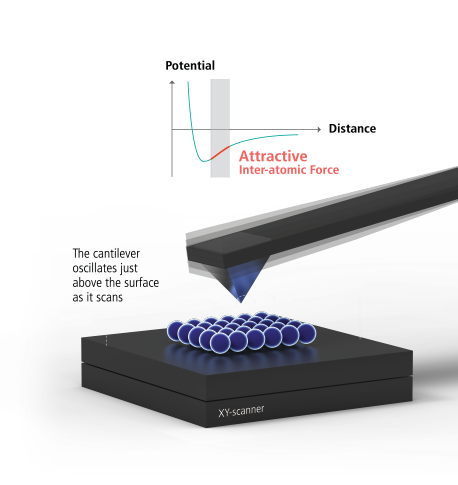

Better tip life, sample preservation, and accuracy with True Non-Contact™ Mode

True Non-Contact™ Mode is a scan mode unique to Park AFM systems that produces high resolution and accurate data by preventing destructive tip-sample interaction during a scan.

Unlike in contact mode, where the tip contacts the sample continuously during a scan, or in tapping mode, where the tip touches the sample periodically, a tip used in non-contact mode does not touch the sample. Because of this, use of non-contact mode has several key advantages. Scanning at the highest resolution throughout imaging is now possible as the tip’s sharpness is maintained. Non-contact mode avoids damaging soft samples as the tip and sample surface avoid direct contact.

Accurate Feedback by Faster Z-servo enables True Non-Contact AFM

- Less tip wear → Prolonged high-resolution scan

- Non-destructive tip-sample interaction → Minimized sample modification

- Maintains non-contact scan over a wide range of samples and conditions

Furthermore, non-contact mode senses tip-sample interactions occurring all around the tip. Forces occurring laterally to tip approach to the sample are detected. Therefore, tips used in non-contact mode can avoid crashing into tall structures that may suddenly appear on a sample surface. Contact and tapping modes only detect the force coming from below the tip and are vulnerable to such crashes.