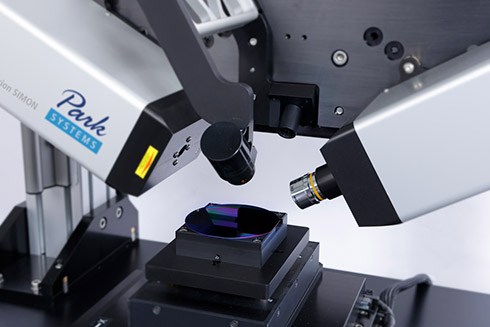

Accurion SIMON

Your Entry to Imaging Ellipsometry

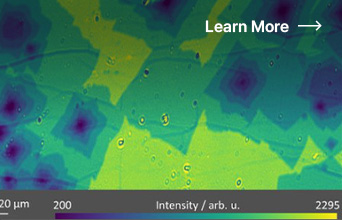

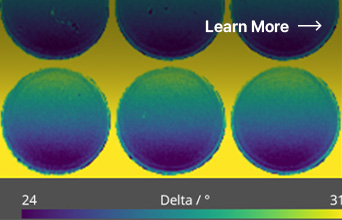

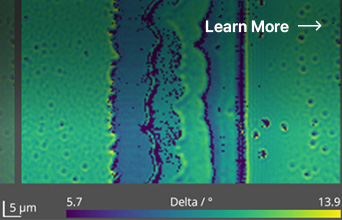

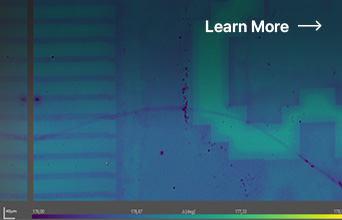

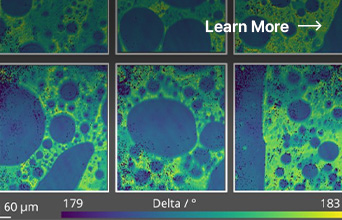

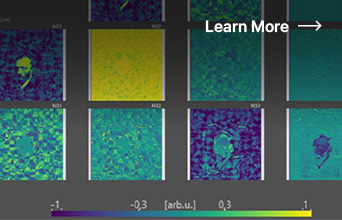

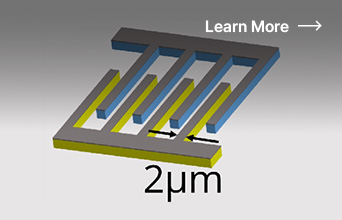

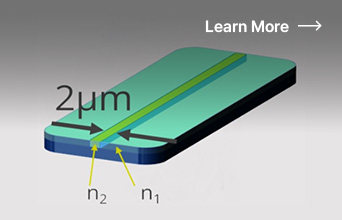

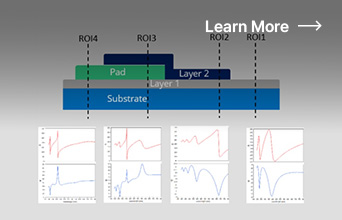

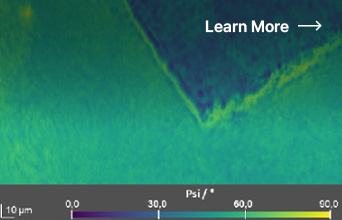

SIMON is specifically designed for routine measurement tasks. Its simple user interface and robustness of a fixed angle ellipsometer enables the entry to imaging ellipsometry. It can be operated in two different modes. The microscopic mode is very fast and allows visualisations of variations and defects in the thinnest layers (e.g., monolayers: d = 0.35 nm), whereas the ellipsometric mode measures thickness and the refractive index of the sample materials. Imaging Ellipsometry itself combines the sensitivity of thickness and refractive index measurements with the imaging capabilities of microscopy. This allows for determining thickness and refractive index variations with microscopic images of e.g., micro-structured samples. Typical applications include the surface inspection of homogeneities and defects in large samples in quality control or the fast localization of flakes of 2D materials.