Contact mode is a standard imaging mode of Atomic Force Microscopy (AFM) that can obtain topographic information on a wide range of sample types.

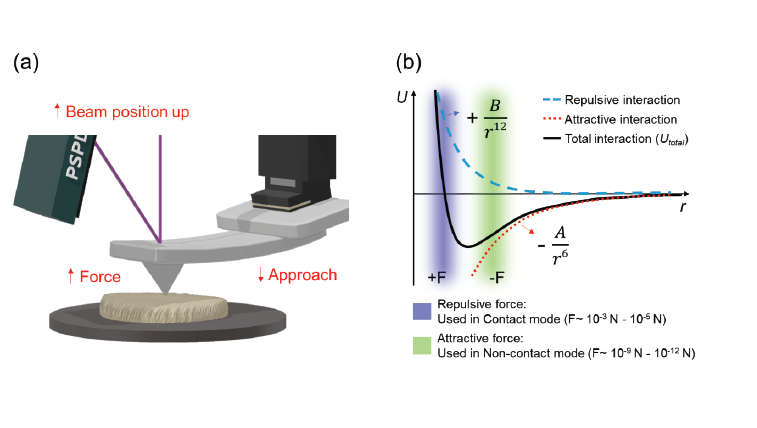

Contact mode is a standard imaging mode of Atomic Force Microscopy (AFM) that can obtain topographic information on a wide range of sample types. In contact mode, feedback is typically obtained through cantilever bending, which employs a low spring constant to minimize sample damage. During contact mode imaging, as the scanner traces the tip across the sample, the repulsive contact forces between the tip and the sample bend the cantilever. This bending accommodates changes in topography, as depicted in Figure 1 (a). For more details, please refer to the Lennard-Jones potential curve in Figure 1 (b), which represents the distance dependence of tip-sample interactions. As the outermost atoms of the tip and the sample are gradually brought closer, they start to attract each other weakly. This attractive force increases until the inter-atomic distance is small enough to trigger the Pauli repulsion between their electron clouds. As the distance between atoms continues to decrease, strong repulsion swiftly counteracts the attractive force. A balance of these interatomic forces is achieved when the distance between the atoms is reduced to a few angstroms, about the length of a chemical bond.

Figure 1. (a) Cantilever bending due to the repulsive contact forces and (b) inter-atomic interaction potential U vs. distance r. The blue curve represents a purely repulsive interaction, while the red curve represents a purely attractive interaction. The black curve is a combination of long-range attractive and short-range repulsive interaction forces called the Lennard-Jones potential. At larger distances, the net force is attractive (-F), which switches to a net repulsive force (+F) when two atoms are brought closer together.