The Most Intelligent Operating Software

Start to finish with 3 clicks of Park SmartScan™

.gif)

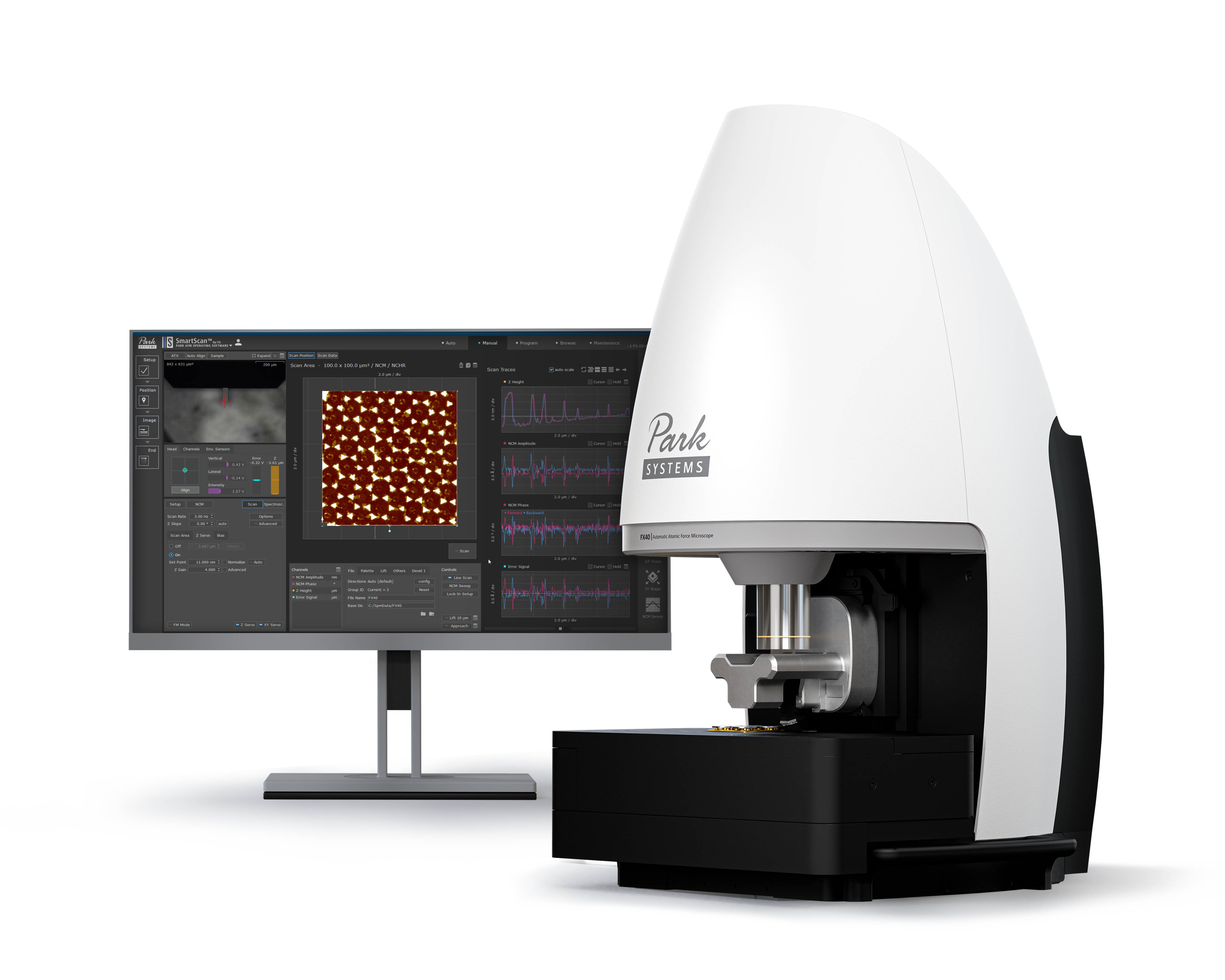

Park FX40 transforms atomic force microscopy, placing user benefits at the forefront through groundbreaking autonomy and advanced technology. Integrated intelligence and robotics automate set up and scanning tasks, freeing researchers from manual operations. This includes managing probes, alignment, sample positioning, and imaging optimization, allowing users to focus on their specialized work. With improved electromechanics, noise reduction, and multi-sample imaging, the FX40 streamlines data collection, research workflows, and data publication, empowering accelerated scientific progress and discovery.

The only AFM to automate all setup and scanning processes with the simple click of a button, Park FX40 automatically changes and replaces its own tips, to avoid any contamination or user-related errors. Operators are offered tip choices including the type, model, application, and usage.

With storage capacity for up to four different samples simultaneously on the chuck, the sample camera effortlessly locates the most relevant spot for scanning.

The Probe Identification Camera reads the QR code imprinted on the chip carrier of a newly loaded probe and extracts and displays all pertinent information on each of the tips available, including the type, model, application, and usage. This enables you to quickly select the best probe tip for each job.

With automated probe exchange, you can now replace old probes easily and safely in full automation. Harnessing the convenience of an 8-probe cassette, along with a magnetic controlled mechanism, the Park FX40 autonomously mounts the probes.

Automatic Beam Alignment positions the laser beam onto the proper location of a cantilever and further optimizes the PSPD position both vertically and laterally. It shifts the X,Y and Z axis for clearer images, with no distortion, all autonomously at the click of a button.

.gif)

New tip crash prevention protects the tip and AFM scanner using a combination of software interlock and hardware switch. Through algorithmic programming, the Z stage can’t physically go down any further than the limit of tip collision with the sample surface, allowing you peace of mind for the safety of your sample and AFM.

SmartScan displays and stores measurements from sensors, which measure essential environmental conditions such as temperature, humidity, leveling and vibration. This allows you to compare your scanned images with different environmental channels, providing further environmental indicators for system diagnosis.

Built-in robotics and a machine-learning algorithm detect and warn you about incorrectly placed probes, since you can use either the automatic or manual tip loading feature. Access various error status report during probe loading to make sure you have the highest degree of accuracy.

Start to finish with 3 clicks of Park SmartScan™

.gif)