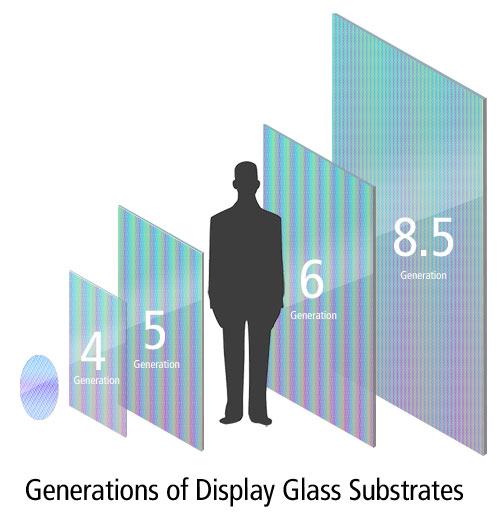

The Automated AFM system for Ultra Large and Heavy Flat Panel Displays at Nanoscale

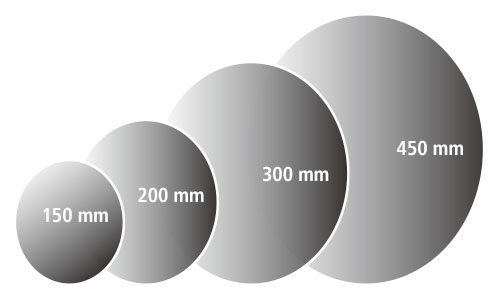

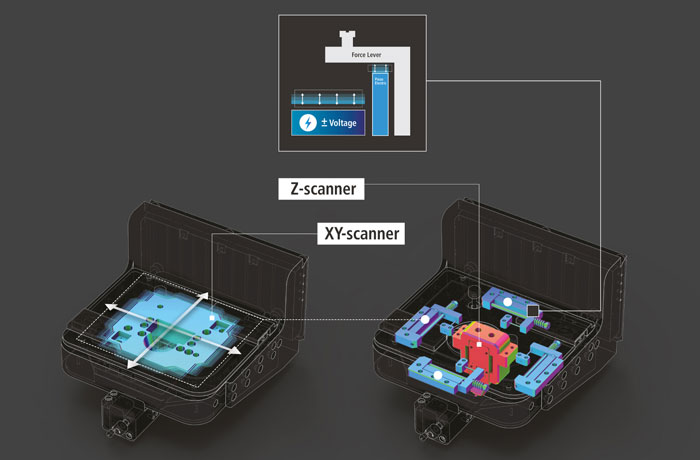

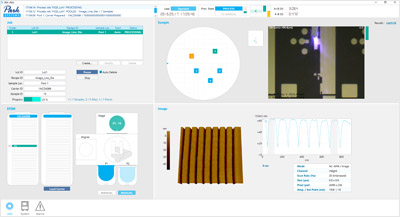

As the demand for Atomic Force Metrology for larger flat panel displays increases, Park NX-Tip Scan Head overcomes nanometrology challenges for samples over 300mm. The Tip Scanning Head and gantry style air-bearing stage allows Park NX-TSH to accurately image roughness measurement, step height measurement, critical dimension measurement. Atomic force microscopy is the most accurate, and non-destructive, method of measuring samples at nanoscale and with Park NX-TSH, reliable, high resolution AFM images can be obtained on OLEDs, LCDs, photomasks and more.

.jpg)