Unique Enhanced EFM Capabilities Provided Only by the Park AFM

High Resolution and High Sensitivity Imaging of Electrostatic Force

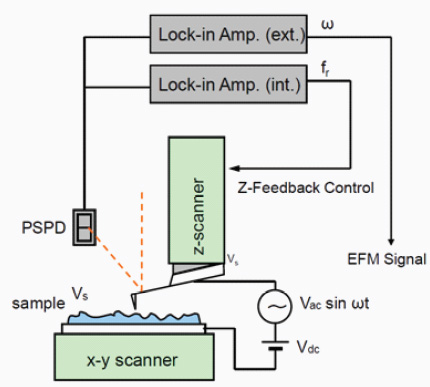

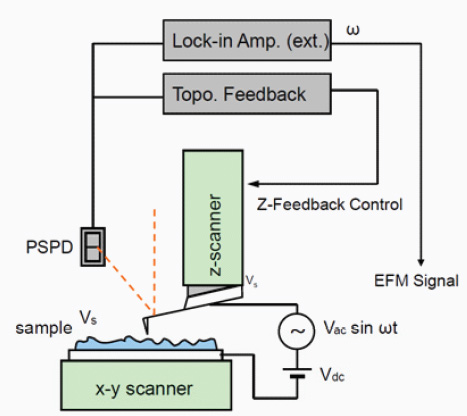

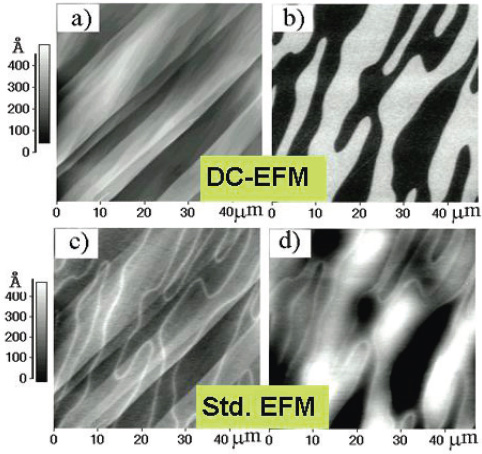

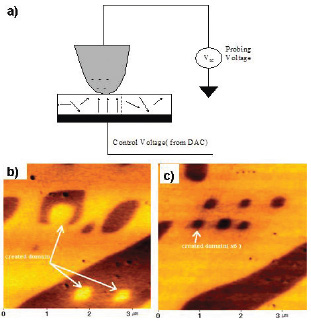

For Electrostatic Force Microscopy (EFM), the sample surface properties investigated are electrical in nature and the interaction force used will be the electrostatic force between a biased tip and sample. However, in addition to the electrostatic force, the van der Waals forces between the tip and the sample surface are always present. The magnitude of these van der Waals forces change according to the tip-sample distance and are therefore used to measure the surface topography. Hence the obtained signal contains both information for both surface topography and surface electrical properties generated by the van der Waals and electrostatic forces respectively. The key to successful EFM imaging lies in the separation of the EFM signal, the information regarding surface electrical properties, from the entire signal. EFM modes can be classified according to the method used to separate the EFM signal.